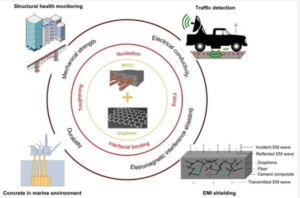

Graphene-supported polymer composites are acquiring consideration because of their uncommon properties and wide applications. Graphene, a two-layered carbon material, improves mechanical strength, electrical conductivity, warm administration, and boundary properties.

When joined with polymer frameworks, graphene enormously improves the exhibition of composite materials. Graphene-supported polymer composites track down applications in different enterprises, including car, aviation, gadgets, energy capacity, and biomedical areas. This blog entry features the significance and capability of graphene-built up polymer composites, investigating their colossal applications and talking about the effect they are ready to make from here on out. At QuantoNano, we mean to give you prevalent quality graphene, taking into account the application regions, future execution assumptions, and benefits of graphene-built up polymer composites.

Introduction

Graphene-supported polymer composites definitely stand out enough to be noticed because of their surprising properties and possible applications in different ventures. Graphene, a two-layered carbon allotrope, has excellent mechanical strength, electrical conductivity, heat scattering capacity, and obstruction properties. When integrated into polymer frameworks, graphene can fundamentally improve the mechanical, electirical, warm, and hindrance qualities of the composites. This presentation gives an outline of the basics of graphene and polymer composites, underlining the significance of graphene support and the synergistic impacts it offers.

Besides, it investigates the manufacture procedures used for making graphene-supported composites and features the portrayal strategies utilized to survey their exhibition. The various benefits and uses of graphene-built up polymer composites are likewise tended to, crossing across businesses, for example, auto, aviation, gadgets , energy capacity, and medication. While challenges connected with adaptability, cost, and long haul strength endure, progressing innovative work tries expect to defeat these obstacles and open the maximum capacity of graphene-built up polymer composites later on.

Graphene and Polymer Composites: Fundamentals

Graphene and its Properties

The two-layered allotrope of carbon known as graphene is comprised of a solitary layer of carbon molecules coordinated in a hexagonal cross section. It is regularly alluded to as a “wonder material” due to its remarkable characteristics and boundless potential for many purposes. Here is a rundown of graphene’s principal credits:

Structure: One iota of graphene is all that isolates it from being a level sheet. Solid covalent associations between the carbon iotas in the sheet structure a grid that looks like a honeycomb.

Mechanical Strength: Graphene is especially firm areas of strength for and. It is one of the most grounded materials yet found, with an elasticity of about 130 gigapascals (GPa). Moreover, because of its extraordinary level of adaptability, it could extended without break.

Electrical Conductivity: Graphene is a very electrical transmitter. It has a high electron versatility, which diminishes the opposition looked by electrons as they course through the design. Due to this trademark, graphene might be utilized in hardware parts including semiconductors, sensors, and conductive coatings.

Heat Conductivity: The intensity conductivity of graphene is very great. Solid carbon holding and huge phonon portability inside its construction empower effective intensity transmission. Graphene is profitable for applications in warm administration, for example, heat sinks or warm connection point materials, due to its element.

Basics of Polymer Composites

A polymer network and a supporting material are joined to shape polymer composites, which can have at least two parts. To work on the mechanical, warm, or electrical attributes of the polymer lattice, the building up material — frequently as filaments, particles, or pieces — is dispersed inside it. A portion of the basics of polymer composites are as per the following:

Polymer Matrix: The ceaseless period of the composite that gives the material its design and attachment is the polymer lattice. It very well may be a polymer that is thermoplastic or thermosetting. While thermosetting polymers, similar to epoxy or polyester, experience irreversible restoring when warmed, thermoplastic polymers, similar to polyethylene or polystyrene, may over and again dissolve and harden.

Reinforcing Material: To improve specific characteristics of the composite, supporting material is incorporated into the polymer lattice. It can take the state of pieces (like graphene or mica) or particles (like silica or earth). It can likewise appear as filaments (like carbon, glass, or aramid). Expanded strength, solidness, sturdiness, or other advantageous characteristics might result from the utilization of the building up material.

Dispersion: To accomplish a homogeneous scattering, the supporting material is spread all through the polymer network. Strategies including impregnation, soften blending, arrangement blending, or in situ polymerization can be utilized to achieve this.

Applications: Polymer composites are utilized in different fields, including hardware, airplane, car, building, from there, the sky is the limit. They are utilized in the development of lightweight yet solid parts, for example, those found in outdoor supplies, vehicle boards, wind turbine cutting edges, and flying parts. Furthermore, they have benefits concerning plan opportunity, erosion opposition, and custom material characteristics.

Importance and Benefits of Graphene Reinforcement

A significant progression in material science, the building up of polymers with graphene offers various significant advantages. Coming up next are a portion of the primary advantages and meaning of graphene support:

Improved Mechanical Properties: The high elasticity, inflexibility, and durability of graphene contribute essentially to improving the mechanical strength, modulus, and sturdiness of polymer composites. These materials can be important for supporting military gear and designs. For example, graphene-built up polymer materials can upgrade the strength of ballistic security plates utilized in protective layer frameworks or work on the blend of lightweight and solidness in composite materials utilized in military vehicles.

Superior Electrical Conductivity: In light of the fact that graphene is a decent electrical conduit, the composites that are delivered have a high electrical conductivity. Applications for this quality incorporate hardware, sensors, electromagnetic impedance protecting, and energy capacity technologies. Polymers might be made electrically conductive utilizing graphene support without losing other wanted highlights.

Thermal Conductivity and Intensity Dissipation: Graphene really disperses heat because of its fantastic warm conductivity. Graphene expands the warm conductivity of polymers and makes it feasible for further developed heat dispersal. Applications requiring proficient warm administration, such electrical hardware or intensity sinks, can profit from this trademark.

Improved Boundary Properties: Graphene support can work on the polymer’s capacity to go about as a gas and fluid hindrance. A tangled channel made by the particular construction of graphene sheets or particles keeps synthetics from saturating through the composite material. Applications for this characteristic incorporate bundling, defensive coatings, and obstruction films.

Lightweight: Graphene is an extremely light substance all by itself. It helps with keeping up with or in any event, bringing down the all out weight of the material while likewise further developing its mechanical characteristics when utilized as a support in polymer composites. This is especially critical in areas like airplane and auto, where weight decrease is fundamental for upgrading execution and efficiency.

Flexibility and Processability: Reinforcement made of graphene might be added to polymers in different ways, like sheets, pieces, nanoparticles, or functionalized subsidiaries. Because of its versatility, graphene might be integrated into an assortment of polymer lattices, considering adaptability in the creation cycle. Expulsion, infusion embellishment, and 3D printing are normal strategies for handling polymers supported with graphene.

Benefits for the climate: Graphene support could assist with ecological drives. Improving the presentation of polymer materials might assist with eliminating material use and increment item life expectancy, bringing about less waste creation and asset utilization. Also, contrasted with other supporting materials, graphene itself might be delivered from feasible carbon sources, in this manner giving ecological advantages.

Synergistic Impacts of Graphene-Polymer Combination

In composite materials, the expansion of graphene to polymers can have synergistic impacts that significantly work on the composite’s characteristics over the amount of its parts. Coming up next are a few huge synergistic impacts in graphene-polymer mixes:

- Electrical Conductivity

- Mechanical Reinforcement

- Temperature Conduction

- Barrier Features

- Enhanced dispersion

- Multifunctionality of the interface

These synergistic impacts make graphene-polymer composites exceptionally engaging for different applications, from hardware and auto parts to bundling, energy capacity, and aviation and vehicle parts. The graphene-polymer blend will be additionally improved by means of progressing innovative work, and new purposes for these refined composite materials will be researched.

Fabrication Methods for Graphene Supported Polymer Composites

Graphene built up polymer composites are materials that increment the mechanical, warm, and electrical qualities of the composite by melding graphene, a two-layered carbon allotrope, with a polymer lattice. Graphene built up polymer composites are made utilizing an assortment of assembling processes, including:

- Solution Blending/Blending

A homogenous mix of graphene and a polymer arrangement might be made. The polymer arrangement can be joined with graphene that has been scattered in a dissolvable. To work with the scattering of graphene in the dissolvable, various techniques including sonication and high velocity blending are utilized. To make the composite material, the resultant blend can either be projected or dissipated utilizing a dissolvable.

- Melt Handling (a)

Graphene is integrated into a liquid polymer during the melting system. Typically, twin-screw expulsion or infusion forming processes are utilized to integrate the graphene into the polymer soften. To make the graphene supported polymer composite, the liquid combination is accordingly cooled and cemented. Most thermoplastic polymers are handled utilizing a liquefy.

- In Situ Polymerization (b)

In this technique, graphene is acquainted with a monomer arrangement, and polymerization is begun in its presence to make the polymer network. During the polymerization cycle, graphene fills in as a layout and is integrated into the polymer grid. This procedure further develops command over graphene scattering however requires specific monomers and response conditions.

- Electrospinning

Polymer filaments with widths in the nano-to micrometer range are made utilizing the electrospinning process. To make graphene built up polymer nanofibers, graphene can be added to the polymer arrangement utilized for electrospinning. The arrangement of graphene inside the strands is worked with by the electrospinning system, working on the mechanical attributes.

- Layer-by-Layer Assembly

To construct a stacked design, his technique on the other hand stores polymer layers and graphene sheets. Using strategies like splash covering, plunge covering, or twist covering, each layer is applied. The specific control of the graphene piece and design inside the composite is made conceivable by the layer-by-layer development.

- 3D Printing

The production of graphene supported polymer composites has created extraordinary interest in 3D printing, regularly alluded to as added substance fabricating. It gives exceptional advantages including plan flexibility, complex calculations, and the ability to create tweaked structures.

It is influential for recollect that the determination of the assembling technique is impacted by various factors, including the expected characteristics of the composite, the picked polymer framework, and the arranged application. Moreover, functionalized graphene or surface-changed graphene can be utilized to expand the scattering and interfacial cooperations with the polymer, working on the presentation of composites.

Characterization of Graphene Built up Polymer Composites

Mechanical Testing: Strength, Sturdiness, and Stiffness

While assessing graphene built up polymer composites precisely, many testing procedures are utilized to check the materials’ solidarity, firmness, and durability. Influence testing looks at the composite’s ability to retain energy during unexpected hits, flexural testing measures the composite’s conduct under bowing tensions, and ductile testing checks the composite’s reaction to extending powers. These examinations offer significant experiences into the upgrades in mechanical attributes welcomed on by the expansion of graphene to the composite material.

Electrical and Warm Conductivity Analysis

The limit of graphene supported polymer composites to direct power and intensity is assessed utilizing electrical and warm conductivity studies. Lower opposition demonstrates expanded electrical conductivity due to graphene, as per an electrical conductivity examination that breaks down the obstruction or sheet opposition of the composite. Higher warm conductivity demonstrates further developed heat dissemination abilities due to graphene, as indicated by an assessment of the composite’s ability to lead heat. These assessments help with deciding whether the composites are reasonable for utilizes requiring compelling electrical conduction or intensity dissemination.

Morphological and Underlying Characterization

Dissecting the actual cosmetics, arrangement, and appropriation of graphene inside the composite takes into account morphological and underlying assessment of graphene built up polymer composites. Morphological characterisation incorporates strategies like filtering electron microscopy (SEM) and transmission electron microscopy (TEM) to examine the surface and inside structure. While doing primary characterisation, techniques including X-beam diffraction (XRD) and Fourier-change infrared spectroscopy (FTIR) are utilized to analyze the gem construction, direction, and interfacial associations. These portrayals assist with the composites’ enhancement and application-explicit personalization by offering helpful bits of knowledge into their morphology, circulation, and primary qualities.

Chemical and Actual Properties Evaluation

physical and synthetic attributes It involves assessing the compound make-up, warm strength, mechanical qualities, and electrical conductivity of graphene built up polymer composites. For dissecting synthetic creation, strategies like FTIR and Raman spectroscopy are used, while TGA and DSC are utilized to survey warm soundness. The mechanical attributes of the composite are assessed utilizing influence and ductile testing techniques. The composite’s ability to direct power is estimated by electrical conductivity. These investigations offer savvy information on the synthetic way of behaving, warm execution, mechanical strength, and electrical conductivity of the composite, permitting analysts to understand and improve its qualities for specific applications.

Performance Upgrades with Graphene Reinforcement

Mechanical Execution Improvement

The mechanical presentation of polymer composites is improved by graphene support. It improves weight decrease, solidness, strength, and weariness resistance. Composites built up with graphene have better burden bearing limit, solidness, influence obstruction, sturdiness, and weight potential. They are looked for superior execution applications in various areas because of these upgrades.

Enhanced Electrical and Warm Conductivity

In polymer composites, graphene support works on warm and electrical conductivity. It improves the composite’s electrical conductivity, making it adequate for involves that call for powerful electrical conduction. Furthermore, the composite’s upgraded limit with regards to warm conduction makes graphene support helpful for applications requiring effective intensity dispersal. The graphene stacking and dissemination might be acclimated to change the conductivity characteristics. By and large, enterprises that request further developed electrical and warm conductivity can profit from the multifunctionality and expanded application choices presented by graphene-built up composites.

Barrier Properties and Gas Permeability

Polymer composites with graphene support have better boundary characteristics and have less gas entrance. The expansion of graphene sheets works on the composite’s ability to work as a boundary material by shaping an obstruction that forestalls the progression of gases and fluids. Applications that call for low gas porousness, such bundling, coatings, and films, can profit from this trademark. By adjusting the stacking and dispersion of graphene, the gas obstruction execution might be altered. Generally, the expanded obstruction characteristics and diminished gas porousness of graphene-supported composites make them proper for different applications.

Flame Retardancy and Fire Resistance

Polymer composites with graphene support have further developed imperviousness to fire and fire retardancy. It fills in as a hindrance against intensity and oxygen, decreases combustibility, and restrains the spread of blazes. Composites reinforced with graphene have better imperviousness to fire, produce less smoke, and may even self-douse. These highlights assist individuals with complying with fire regulations and further develop fire security.

Applications of Graphene Supported Polymer Composites

- Automotive and Aviation Industry

Graphene-supported polymer composites in the auto area offer lightweighting, expanded strength and firmness, more prominent effect obstruction, and electrical conductivity. They are utilized in vehicle gadgets, EV battery frameworks, underlying parts, and clamor and vibration hosing.

Graphene-supported polymer composites in the aviation area offer lightweight development, elite execution parts, upgraded warm administration, electrical conductivity, and more prominent wellbeing. They are utilized in aviation hardware, warm obstructions, airplane parts, and primary uprightness expansion.

- Electronics and Energy Storage

Composites built up with graphene are utilized in electrical and electronic hardware. Printed circuit sheets, sensors, conductive coatings, and electromagnetic safeguarding may all utilize them on account of their prevalent electrical conductivity and mechanical characteristics.

Lithium-particle batteries and supercapacitors are two instances of energy stockpiling frameworks that utilization graphene-supported composites. Their capacity for energy capacity, temperature control, and electrical conductivity are completely worked on by the utilization of graphene.

- Biomedical and Medical services Applications

Clinical purposes for graphene-supported composites incorporate tissue designing, drug conveyance gadgets, and muscular inserts. They have characteristics that are profitable for clinical gadgets and regenerative medication, including as biocompatibility, mechanical strength, and electrical conductivity.

- Construction and Infrastructure

Composites supported with graphene may track down use in the structure area. They might be utilized to support substantial developments, expanding their solidness and mechanical strength. They can likewise be utilized to serious areas of strength for make, development materials.

Challenges and Future Outlook

Despite the fact that graphene-built up polymer composites have a ton of potential, various issues should be settled before they can be broadly utilized. Here are a portion of the central concerns and the possibilities for what’s to come:

Scalability and Cost Considerations

The expense viability of graphene-supported composites is at present affected by the significant expense of graphene fabricate. To make these composites all the more monetarily suitable, upgrades in huge scope creation strategies and cost-cutting procedures are required.

It is as yet hard to scatter and situate graphene in polymer networks consistently for a huge scope. Commercialization relies upon increasing the creation interaction while keeping steady quality and attributes

Durability and Long haul Stability

It’s urgent to grasp the drawn out sturdiness and maturing conduct of graphene-supported composites for their predictable exhibition over the course of time. To assess their dependability, processes for disintegration, and protection from natural impacts, more review is required.

Future Prospects

Regardless of the troubles, graphene-supported polymer composites have a brilliant future in front of them. These issues are forcefully addressed by scholastics and business pioneers to understand the maximum capacity of these composites. Here are a few essential regions for future development:

Improved Assembling Techniques: Graphene-supported composites’ creation productivity and versatility can be expanded on the grounds that to enhancements in assembling strategies including added substance fabricating and constant assembling methodology.

Advancing Electronic Properties: Graphene-supported composite attributes are overall further explored to be streamlined for specific applications. This involves investigating cross breed mixes with different supporting materials as well as refining the stacking, scattering, and arrangement of graphene.

Composites with numerous functions: By consolidating graphene with different substances like nanoparticles or filaments, composites with various capabilities can be made that have worked on mechanical strength, electrical conductivity, warm solidness, and self abilities to mend.

Sustainable and harmless to the ecosystem solutions: Graphene and composites supported with it are being delivered utilizing harmless to the ecosystem and maintainable techniques. This involves investigating feasible graphene sources and utilizing bio-based or reused polymers as framework parts.

Real-World Applications: Graphene-supported composites will turn out to be all the more generally utilized later on in various fields and applications, including auto, aviation, gadgets, energy capacity, and medical care. These composites could change current innovation and make it conceivable to make fresh out of the box new, state of the art arrangements.

Conclusion

All in all, graphene-supported polymer composites enjoy a few benefits and planned involves in various fields. They have remarkable boundary attributes, fire retardancy, electrical and warm conductivity, and mechanical characteristics. Despite the fact that there are still issues with cost, versatility, handling techniques, and normalization, the possibilities for graphene-supported composites in the future are hopeful.

Future forward leaps are being driven by enhancements underway techniques, specific property streamlining, ecological drives, and the fuse of graphene with different materials. The auto, aviation, gadgets, energy capacity, development, and clinical areas, among others, could be generally totally changed by these composites.

Graphene-built up polymer composites are expected to fundamentally further develop execution, effectiveness, and security in different applications with proceeded with study and specialized improvement. With their unmistakable characteristics and versatility, they give interesting open doors to development and have the ability to impact the bearing of entire areas.

Leveraging state of the art innovations and prevalent materials, QuantoNano rethinks your endeavors and slings your business to novel aspects.