Lithium-particle battery reusing is critical for supportability, recuperating important materials through different methods to satisfy expanding need and diminish ecological impact.

Lithium-particle batteries assume a vital part in energy capacity advances, like cell phones, electric vehicles, and environmentally friendly power frameworks. Nonetheless, with the rising utilization of these batteries, the administration and reusing of battery squander have become huge worries. Reusing lithium-particle batteries is of central significance for the recuperation of important materials and lessening natural effects. At QuantoNano, we focus on natural supportability and endeavor to lessen our biological impression. We offer fundamental parts that add to manageable practices.

Introduction

Lithium-particle batteries (LIBs) were first monetarily delivered in 1991 and have since become fundamental in different advancements like vehicles, customer hardware, power devices, clinical gear, and reinforcement power frameworks. They comprise of a cathode and anode where decrease and oxidation responses happen. An electrically protecting separator, regularly a microporous polymer layer, isolates the cathode from the anode to forestall shortcircuiting. The electrolyte is in touch with the two anodes, permitting the exchange of lithium particles while obstructing the progression of 2 electrons. Flow gatherers interface with an outside circuit to gather the created electrical flow.

Lithium-particle batteries comprise of a few fundamental parts. The cathode materials, regularly made of a lithium-based metal oxide, for example, lithium cobalt oxide (LiCoO2) or lithium iron phosphate (LiFePO4), gives a construction to the convenience and arrival of lithium particles. The anode materials, generally made out of graphite, stores and deliveries lithium particles. The electrolyte works with the development of lithium particles. The separator actually isolates the anodes while permitting the section of lithium particles. Flow authorities assemble and move the electrical flow. These parts cooperate to empower the proficient working of lithium-particle batteries.

Understanding the Two Battery Classes: Lead Corrosive and Lithium-ion

Lead corrosive batteries have for quite some time been utilized to drive gas powered motor vehicles and store energy for different vehicle embellishments. Notwithstanding, as innovation advances, lithium-particle batteries have arisen as a predominant other option. The essential benefit of lithium-particle batteries lies in their higher energy thickness and longer life expectancy, making them more productive and solid contrasted with lead-corrosive batteries.

The flexible idea of lithium-particle batteries has prompted their rising reception in different applications, like framework frameworks and transportation. These batteries are made out of lithium particles, alongside extra parts like nickel, manganese, and cobalt.Their special usefulness considers the thick stockpiling of power by changing over electrical energy into synthetic energy.

Battery security is pivotal, and progressions have made batteries more secure for energy capacity. In electric vehicles, a solitary cell disappointment won’t harm the whole framework whenever planned with security in mind. Lithium-particle batteries consolidate wellbeing highlights to relieve risks. Huge scope sustainable power establishments focus on wellbeing measures. Improving cycles and investigating arising advances will upgrade battery execution and lower costs. Moral obtaining of materials like lithium, nickel, cobalt, manganese, and graphite is fundamental for maintainability. Battery progressions drive decarbonization and advancements in mining, charging foundation, and vehicle-to-network applications.

Benefits of Li-particle Battery Recycling

Environmental Benefits

Reduces the requirement for new mining: Reusing lithium-particle batteries limits the interest for new mining exercises, decreasing the ecological effect related with separating metals like cobalt, nickel, and lithium. This helps moderate regular assets and safeguards biological systems.

Decreases ozone depleting substance emissions: Reusing batteries lessens the requirement for energy-escalated mining and assembling processes, bringing about lower ozone depleting substance discharges. It adds to the general objective of lessening carbon impression and fighting environmental change.

Prevents perilous waste: Appropriate reusing of batteries guarantees the protected removal of harmful and risky materials present in batteries, for example, arsenic compounds. This forestalls expected defilement of soil and water sources.

Resource Protection Benefits

Preserves important metals: Reusing lithium-particle batteries considers the recuperation and reuse of significant metals like cobalt, nickel, and lithium. This lessens the requirement for unrefined substance extraction and moderates these limited assets.

Enhances store network security: By reusing battery materials, the business decreases its reliance on unstable worldwide stock chains. Homegrown accessibility of reused materials gives greater strength and security in obtaining battery parts.

Economic Benefits

Reduces creation costs: Reusing batteries can bring down the general expense of lithium-particle battery creation by giving a more practical wellspring of materials. This cost decrease can add to making battery advances more reasonable and available.

Creates work opportunities: Battery reusing offices and cycles require talented work, prompting the making of occupations in the reusing area. This can add to neighborhood financial development and maintainability.

Energy Productivity Benefits

Saves energy in material extraction: Reusing batteries takes out the requirement for energy-serious mining processes, decreasing the energy utilization related with essential material extraction. This adds to generally speaking energy protection endeavors.

Reduces energy utilization in manufacturing: Reusing materials from utilized batteries can assist with preserving energy by diminishing the energy-concentrated processes engaged with assembling new battery parts. This prompts energy reserve funds and a more proficient utilization of assets.

Challenges of Li-particle Battery Recycling

Increasing Request and Unrefined substance Shortages

-The quick development of electric vehicle (EV) creation and the progress to net-zero outflows have prompted a flood in the interest for battery-related natural substances, for example, nickel (Ni), cobalt (Co), manganese (Mn), lithium (Li), and graphite.

-Satisfying the expected need for these natural substances acts difficulties like the worldwide store network might confront critical lead times and possible deficiencies, especially for lithium and cobalt.

Environmental Effect and Inappropriate Handling

-The life expectancy of lithium-particle batteries (LIBs) goes from 1-3 years for purchaser gadgets to 8-10 years for EVs and energy stockpiling frameworks. Thus, a significant measure of utilized LIBs is supposed to be produced soon.

-Inappropriate dealing with and removal of spent LIBs can prompt natural issues, including the arrival of poisonous weighty metals like cobalt, nickel, manganese, and unsafe gases like hydrogen fluoride (HF) into the climate.

-Collection of utilized LIBs without legitimate administration builds the gamble of fire and blasts, featuring the significance of safe taking care of and reusing rehearses.

Recycling as a Solution

-Seeing utilized LIBs as important assets, their inside parts can be viewed as battery-grade and reasonable for reuse in assembling new batteries.

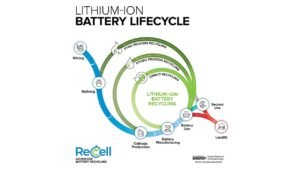

-Reusing utilized LIBs presents a potential chance to lay out a roundabout inventory network by once again introducing recuperated materials into the creation of new batteries, decreasing dependence on virgin unrefined components.

Techniques and Innovations to Conquer Reusing Challenges

Business reusing activities vigorously depend on extricating significant cathode parts from LIBs (Lithium-ıon batteries) to produce income. In any case, the decrease of cobalt content in new cathode material sciences presents monetary difficulties for conventional LIB reusing. Research amazing open doors incorporate improving dismantling advancements, arranging techniques, general reusing processes, planning for reusing, and battery normalization to diminish expenses and upgrade plans of action. It is essential to improve current reusing innovations to guarantee productivity and monetary suitability.

Energy effectiveness is a critical thought in battery recycling. Reusing current gatherers and cathode materials can essentially decrease energy use, while reusing any recyclable cathode materials helps lower ozone harming substance emanations. The decision of reusing innovation and the limit usage of batteries additionally impact energy investment funds. Hydrometallurgical and pyrometallurgical techniques offer different energy-saving possibilities, with actual methodologies by and large requiring lower handling temperatures. Battery type decides the most appropriate reusing rehearses, with hydrometallurgical procedures liked for specific batteries and pyrometallurgical methods for other people. Be that as it may, consistent progressions in battery innovation make reusing really testing and require continuous enhancements in reusing techniques.

Lithium-particle Battery Reusing Philosophies

- Direct Reusing: This technique includes genuinely isolating the battery parts and dismantling the batteries to hold the cathode material for reuse in LIBs. Direct reusing requires less energy and assets contrasted with different procedures, yet it expects work to isolate the battery parts for reuse.

- Pyrometallurgical Processes: Pyrometallurgical processes utilize nuclear power, ordinarily created by the ignition of the battery shell and natural parts, to decrease battery parts to metals and slag that can be isolated. While pyrometallurgy can’t recuperate lithium, it tends to be utilized to reuse an assortment of battery types with lower energy and capital costs contrasted with different methodologies, not restricted to LIBs.

- Hydrometallurgical Processes: Hydrometallurgical processes include eliminating metal parts from batteries involving fluid arrangements and specifically encouraging explicit metal mixtures for recuperation. Contrasted with pyrometallurgy, hydrometallurgy requires less energy and has lower office costs, yet it uses more synthetics and water in the battery creation process. Pretreatment strategies are likewise essential for both pyrometallurgical and hydrometallurgical cycles to set up the battery materials for additional processing.

Conclusion

Lithium-particle battery reusing is fundamental for manageability, decreasing the requirement for new mining, bringing down discharges, forestalling dangerous waste, and protecting important assets. Conquering difficulties and further developing reusing procedures will add to a roundabout economy and limit the ecological effect of lithium-particle batteries.At QuantoNano, we are committed to manageability and molding the eventual fate of batteries with our imaginative materials. Join us in making a greener tomorrow.