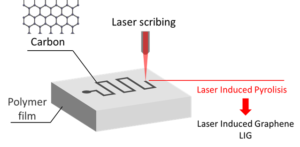

A 3D permeable substance known as laser-prompted graphene (LIG) is made by straightforwardly composing carbon materials with a CO2 laser while they are in a surrounding climate. This technique wipes out the necessity for wet synthetic stages by joining the readiness and designing of 3D graphene into a solitary step.

A few articles feature the interpretation into various application fields and to frame the mechanics of the LIG-shaping cycle. The strategies that have been laid out to make LIG are illustrated underneath, remembering the improvement for way to deal with change different carbon antecedents into LIG and the administration of LIG credits including porosity, content, and surface characteristics.The utilizations of LIG in different areas, for example, microfluidics, sensors, and electrocatalysts, are stressed by using the LIG highlights. At last, a concise conversation of impending improvements in biodegradable and biocompatible materials is given. Quanto Nano, one of the spearheading organizations on the planet to start large scale manufacturing of graphene, offers excellent graphene items to add to your scholarly exploration and upgrade your projects.

Introduction

Because of their extraordinary physical and compound qualities, graphene-based materials (GBMs) certainly stand out for their huge potential for different helpful gadgets. As of late, laser direct composition (LDW) innovation has offered a powerful handling approach for the great many uses of laser-prompted graphene (LIG) that doesn’t depend on either high temperature or hurtful chemicals.This article’s goals are to refresh the latest discoveries in this rapidly creating subject and to offer pivotal experiences that will spike new and fascinating LIG developments and its functionalization. We investigate the different approaches to getting ready and functionalizing LIG, including instigating, organizing, doping, and hybriding, in view of the collaboration components and actual outcomes. The utilizations of LIG and its GBMs designed by LDW approach in the fields of optoelectronic gadgets, energy capacity gadgets, biosensors, and biomimetic gadgets were canvassed in this progress report.

At the point when laser-prompted graphene was first created from a plastic substrate in 2013 by Teacher James Visit at Rice College, the marvel material’s actual potential became clear. From that point forward, research on laser-prompted graphene has prompted the improvement of state of the art materials. Utilizing the laser-actuated graphene procedure, various scholarly gatherings are doing explore and making novel applications. Among the numerous enterprises ready to assist humankind, major LIG applications with including air filtration, water decontamination, sensors, bio-sensors, adaptable hardware, and energy.

Synthesis and Designing of Laser-Instigated Graphene

Since LIG requires essentially a standard laser that can be found in any machine shop and no solvents or synthetic reagents, it is a naturally harmless, financially reasonable, and versatile technique.

A 10.6 m laser photothermally warms the carbon forerunner to > 2500 °C throughout the span of microseconds to make laser-instigated graphene. Thus, non-carbon molecules quickly outgas, and the excess carbon is urged to go through sp2 hybridization. The porosity microstructure of LIG is made because of the communication among outgassing and sp2 hybridization. Graphene nanomaterial creation and designing are hard to financially do. Our procedure settle the issue. By utilizing a laser shaft and business polymer films, LIGC fosters a one-step, versatile strategy for creating and planning 3D organizations of permeable graphene sheets.

Properties of Laser Initiated Graphene technology:

- Conductive

- Flexible

- Anti-Microbial

- Hydrophobic

- Hydrophilic

What Job Does Laser-Actuated Graphene Play in Current Technology?

Filtration

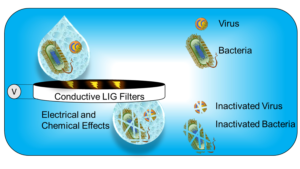

The permeable idea of laser-initiated graphene makes it ideal for separating applications. The two particles and microorganisms can be successfully caught utilizing sub-micron pore breadths. In fact, an extensive variety of molecule and organism sizes can be caught by the LIG on the grounds that its pore widths range from nanometers to microns. LIG has so exhibited progress in delivering filtration media for the cleaning of both air and water. A LIG-based air filtration framework has been made by LIGC Applications to gather and dispense with airborne microbes, infections, and particulates. Like a bug zapper, an electrical flow is communicated through the conductive graphene filtration layer and shocks the caught microorganisms and infections. They can help you in making an answer for your filtration needs utilizing LIG, which might be used to work on a scope of filtration membranes.

Water Treatment:

As of late, there has been a huge interest in understanding and forestalling viral contaminations. In regions with naturally tainted drinking water supplies, the improvement of water treatment technologies for viral inactivation or sterilization is essential for contamination control. LIG has antibacterial and antifouling properties because of its electrochemical attributes and unpleasantness. Higher voltages are expected to inactivate infections contrasted with microorganisms. The cycle includes the development of receptive oxygen species and surface electrical impacts. This one of a kind component of LIG empowers its electrochemical sterilization of pathogenic microorganisms, including microscopic organisms and infections, in water and wastewater treatment. In outline, LIG shows guarantee in water treatment because of its filtration abilities, and creating effective frameworks for water cleaning and disinfection can be utilized.

Energy Storage

Power devices, electrolyzes, batteries, and other energy arrangements can involve LIG innovation as a component of their plan for more noteworthy execution. LIG offers answers for cutting edge energy capacity and producing gadgets. Nanomaterials in view of carbon are fundamental components in various energy stockpiling applications. Carbon nanomaterials are commonly utilized as anodes in supercapacitors and anodes in lithium-particle batteries. Future energy stockpiling frameworks can profit from laser-prompted graphene. LIG has a tremendous surface region and is electrically conductive, two pivotal characteristics of energy stockpiling materials. A modest and adaptable type of energy stockpiling is made conceivable by the immediate development of LIG on the outer layer of polymeric sheets. LIG is a material that can be used to further develop current energy stockpiling frameworks and to make new, further developed frameworks.

Laser-prompted Graphene for Super-Capacitors

New energy stockpiling advancements that overcome any issues between lithium-particle batteries and supercapacitors incorporate crossover supercapacitors. Notwithstanding, making high energy cathodes for commonsense applications while keeping up with long haul cycle soundness and a high-rate capacity is as yet an undeniably challenging issue. In this article, we present a simple methodology for combining a laser-scribed graphene/LiNi1/3Mn1/3Co1/3O2 (LSG/NMC) composite for high energy cathode materials for half breed supercapacitors. LSG/NMC composites show extraordinary capacitance maintenance of 98.1% after 1000 cycles at a high current thickness of 5.0 A/g as well as having a high capacitance of up to 141.5 F/g. A NMC spacer between the LSG layers makes a bigger interspace that can act as a successful channel for additional capacity areas and fast access. They likewise affirmed that crossover supercapacitors (H-HTO) with LSG/NMC cathodesand H2T12O25 anodes with an AlPO4/carbon mixture covering layer (H-HTO) offer a momentous 123.5 Wh/kg of energy, 14074.8 W/kg of force, and 94.6% cycle steadiness after 20,000 cycles. This examination shows that the cathode contender for the cutting edge cross breed supercapacitors produced using this recommended material is solid.

They exhibited that half breed supercapacitors have an exceptional energy thickness of 123.5 Wh/kg and a power thickness of 14074.8 W/kg, as well as a fantastic cyclability of 94.6% after 20,000 cycles, which outflanks those of other crossover supercapacitors. They likewise proposed a clever cross breed supercapacitor framework in light of a LSG/NMC cathode and a H-HTO anode.The following synergistic impacts are principally liable for this exceptional electrochemical presentation: I the LSG’s inborn great electrochemical exhibition;

- the mooring of NMC spacers between the LSG layers, which caused isolated graphene,

- the expansion in capacitance brought about by the unexpected impacts of the NMC pseudocapacitive reaction

- the blend of passages and quick pathways (cross breed covering) in the HTO anode These outcomes highlight the chance of a mixture supercapacitor using the LSG/NMC/H-HTO framework as a strong and proficient device for uncommon performance.

Laser-actuated Graphene for Batteries

Because of its flexibility, minimal expense, and usability, laser light is arising as a practical technique for creating 3D graphene. Here, the attention is on the recently evolved utilizations of laser-actuated graphene (LIG) in batteries. As well as having a folio free self-upheld terminal plan, this type of 3D graphitic carbon likewise has high electrical and ionic conductivity, various leveled porosity, and tunable creation after laser exposure.The improvement of LIG blend and its progression for battery applications are completely inspected and tended to. Remembered for this are the uses of LIG as a terminal for lithium-and sodium-particle batteries, an ongoing gatherer for lithium-metal batteries, an electrocatalyst for metal-air batteries, and a host and interlayer for lithium-sulfur batteries. We offer inventive answers for further develop battery execution and expand battery duration. Visit Quanto Nano to buy the battery materials you want.

Sensor Platform

The LIG’s wide surface region, electrical conductivity, simplicity of production, and biocidal nature make it conceivable to make minimal expense sensors and biosensors with phenomenal execution. In the cutting edge world, savvy advancements empower us to keep a practically consistent eye on our environmental elements and wellbeing. To accumulate data that will permit us to make wise decisions, these shrewd gadgets depend on sensors. Subsequently, it is basic to have sensor stages that are dependable, strong, and versatile so they might be used for various applications. The suitable material for the making of sensor advancements is laser-actuated graphene. Particularly, LIG is conductive, taking into consideration electronic checking of LIG-based sensors. Another reasonable detecting stage quality is that LIG has an exceptionally high surface region, which makes it extremely receptive to its environmental factors. To wrap things up, LIG is effectively functionalized to distinguish specific mixtures and natural species. modified throughput sensors for your necessities.

The production of a progression of LIG sensors is supported by the minimal expense of LIG innovation and its simplicity of union, making it a potential choice for modern assembling. A wide assortment of improvements, including various synthetic substances along with sounds, vibrations, and temperature, have been perceived thanks to the sane plan of detecting components. Because of the immense surface region and compound solidness of LIG, these sensors much of the time show extraordinary responsiveness and strength. LIG is an ideal transducer for making an interpretation of contributions to electrical signs because of its high conductivity. Polymer-based unadulterated LIG is oftentimes adaptable and can move to various substrates.

![]()

Surfaces And Practical Composites

Laser-initiated graphene can be incorporated into composites to increment strength, heat move, electrical conductivity, and antibacterial characteristics. Composites can integrate LIG to further develop usefulness. Using novel inserting procedures, LIG can be joined with a few polymers, epoxies, and strong structure supplies like concrete to make composites. LIG can be added to materials to work on their mechanical characteristics while additionally making them electrically conductive. LIG composites likewise have against microbial properties that prevent microscopic organisms from developing inadvertently. LIG has so far been used to make composites from various materials. LIG can explicitly be covered in cement to work as a warmer for deicing. LIG has been utilized to quit stopping up and biofouling in water channels. To increment mechanical strength and electrical conductivity, LIG has likewise been utilized into epoxies.

Conclusion

Because of its particular two-layered design and predominant physical and compound qualities, graphene has been viewed as a promising application material in the field of novel energy transformation and storage. Notwithstanding, the in-process intricacy of customary graphene planning strategies makes it trying to assemble designed structures. Scientists have been giving a great deal of consideration of late to laser-prompted graphene (LIG) innovation, which has various purposes in supercapacitors, batteries, sensors, air channels, water treatment, and so on. We gathered various graphene arrangement procedures in this article. On the pre-arranged LIG’s properties, the impacts of the laser’s handling boundaries, laser type, antecedent materials, and interaction environment were examined.Then, two techniques for delivering LIG on a major scale were momentarily made sense of. The few purposes of LIG in the space of sign distinguishing, ecological security, and energy stockpiling were likewise covered. At last, we gave a fast outline of this innovation’s possible future headings. At Quanto Nano, we follow the likely notable applications in later advancements and add to their improvement consistently.